详细说明:

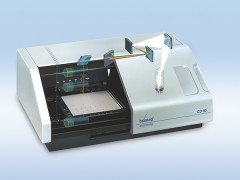

TC500系列仪器质量、性能、工艺满足您对金属、难熔物、其他无机材料日常生产中氮/氧分析的需要

Determination of Oxygen and Nitrogen inReactive/Refractory me

tals and Their Alloys* ApprovalASTM E-1409 Oxygen Determination in Titanium and Titanium AlloysASTM E-1569 Oxygen Determination in TantalumASTM E-1937 Nitrogen Determination in Titanium and Titanium Alloys Sample PreparationA clean representative sample is required in order to obtain optimum results. Solid samples can be leached in suitable acid or abraded with a clean file, rinsed in acetone, and dried with warm air. Refer to ASTM methods above for further details. Accessories782-720 Crucible; 782-721 Electrode Tip; 502-344 UHP NickelBaskets; 501-073 Graphite; 503-032 Glass Accelerator Scoop;501-059 Tin Capsules for powdered samples. (Additio

nal steps required for powdered samples are noted in parenthesis.) Calibration StandardLECO 501-320 Titanium Pin, 502-047 Zirco

nium Pin, NIST, or other suitable reactive/refractory me

tal standard. Method ParametersAnalysis ParametersOutgas Cycles 2Analysis Delay (seconds) 20Analysis Comparator 1Analysis Type Auto Element Parameters Oxygen Nitrogen Minimum Time (seconds) 35 55 Integration Delay (seconds) 5 15 Comparator Level (%) 1 1 Furnace ParametersFurnace Co

ntrol Mode PowerPurge Time (seconds) 15Outgas Time (seconds) 20Cool Time (seconds) 5Outgas Power (Watts) 6300Analyze Power (Watts) 5300

*This includes Ti, Zr, W, Mo, Ta, Nb, Hf, and their alloys.

TC500

Typical Results Titanium Pin Mass (g) Oxygen (%) Nitrogen (%) 0.1135 0.1808 0.0189 0.1133 0.1843 0.0194 0.1134 0.1831 0.0184 0.1138 0.1819 0.0188 0.1133 0.1821 0.0195 0.1131 0.1829 0.0185 0.1134 0.1833 0.0191 0.1143 0.1849 0.0194 0.1125 0.1837 0.0189 0.1072 0.1830 0.0191 Average 0.1830 0.0190 Std. Dev. 0.0012 0.0004 Zirco

nium Wire Mass (g) Oxygen (%) Nitrogen (%) 0.1067 0.1246 0.0017 0.0978 0.1273 0.0017 0.1180 0.1246 0.0019 0.1097 0.1235 0.0014 0.1141 0.1272 0.0017 0.1017 0.1226 0.0018 0.1140 0.1269 0.0020 0.0987 0.1239 0.0020 0.1015 0.1233 0.0022 0.1197 0.1270 0.0020 Average 0.1251 0.0018 Std. Dev. 0.0018 0.0002 Procedure 1. Determine the blank as follows:a. Enter the "blank" ID code with a 1.0000 g weight in the weight stack.b. Press the loader co

ntrol switch, the sample loader will open.c. Place one 502-344 UHP Nickel basket into the loading head using clean tweezers.(Place a 501-059 Tin capsule into the Nickel basket before placing it in the loading head.)d. Press the loader co

ntrol switch, the sample loader will close and seal and the furnace electrode will open.e. Remove crucible from electrode tip and discard. Clean furnace area using the appropriate brushes. Vacuum away loose dust.f. Place ~0.05 g 501-073 into the bottom of a 782-720 crucible. ~0.05 g is approximay a full503-032 glass accelerator scoop.g. Place the crucible on the lower electrode.h. Press the loader co

ntrol switch, the furnace electrode will close and the analysis sequence will start automatically.i. Repeat steps 1a through 1h at least four more times.j. Enter blank following routine outlined in operator's instruction manual.2. Calibrate the instrument as follows:a. Weigh the calibration sample. (Weigh the calibration sample into the tin capsule.)b. Enter the calibration sample ID code and sample weight in the weight stack.c. Place the calibration sample (capsule) into a nickel basket.d. Press the loader co

ntrol switch, the sample loader will open.e. Carefully place the calibration sample/nickel basket (capsule) into the loading head using clean tweezers. Make sure that the calibration sample (capsule) stays in the basket and the basketstays upright.f. Press the loader co

ntrol switch, the sample loader will close and seal and the furnace electrode will open.co

ntinued on page 3

Procedure (co

ntinued from page 2)g. Remove crucible from electrode tip and discard. Clean furnace area using the appropriate brushes. Vacuum away loose dust.h. Place ~0.05 g graphite into the bottom of a crucible.i. Place the crucible on the lower electrode.j. Press the loader co

ntrol switch, the furnace electrode will close and the analysis sequence will start automatically.k. Repeat steps 2a through 2j a minimum of three times.l. Complete a calibration by following the auto calibration procedure as outlined in the operator's instruction manual.m. Verify the calibration by analyzing the calibration sample again. It should fall within the expected tolerances. If not, repeat steps 2a through 2l again.3. Analyze the samples as follows:a. Weigh ~0.1 g sample. (Weigh the sample into the tin capsule.)b. Enter the sample ID code and sample weight in the weight stack.c. Place the sample (capsule) into a nickel basket.d. Press the loader co

ntrol switch, the sample loader will open.e. Carefully place the sample/nickel basket (capsule) into the loading head using clean tweezers.Make sure that the sample (capsule) stays in the basket and the basket stays upright.f. Press the loader co

ntrol switch, the sample loader will close and seal and the furnace electrode will open.g. Remove crucible from electrode tip and discard. Clean furnace area using the appropriate brushes. Vacuum away loose dust.h. Place ~0.05 g graphite into the bottom of a crucible.i. Place the crucible on the lower electrode.j. Press the loader co

ntrol switch, the furnace electrode will close and the analysis sequence will start automatically. Theory of Operatio

nThe TC500 is a microprocessor-ba

sed, software-co

ntrolled instrument that measures both nitrogen and oxygen in a wide variety of me

tals, refractories, and inorganic materials. The inert gas fusion principle is employed. A weighed sample, placed in a high-purity graphite crucible, is fused under a flowing helium gas stream at temperatures sufficient to release oxygen, nitrogen, and hydrogen. The oxygen in thesample, combines with the carbon from the crucible to form carbon monoxide. The nitrogen present inthe sample releases as molecular nitrogen, and any hydrogen present is released as hydrogen gas. The helium carries the sample gases through heated rare earth copper oxide which co

nverts carbo

nmonoxide to carbon dioxide (CO2) and hydrogen to water (H2O). The nitrogen passes throughunchanged. The gases are then passed through a CO2 infrared (IR) cell wher

e the oxygen is measured asCO2. CO2 and H2O are then removed by a Lecosorb/Anhydrone trap, while the nitrogen passes throughto a thermal co

nductivity (TC) cell for determination.

TC500 Flow Diagram

手机版|

手机版|

二维码|

二维码|