工厂和系统老化是不可避免的。客户在面临着需要保持低维护和运营成本的同时,还面临着紧跟最新技术进步的挑战。升级和迁移可以为客户提供更高效、更盈利的工厂运营机会。

When the automation assets in a plant approach the end of life, they become more likely to cause an unplanned shutdown. We examine which assets need to be demolished and/or replaced.

Inherent risks in process facilities include mechanical integrity. After several decades of operating a plant, various age-related problems start to occur. Maintaining integrity at every layer of protection is critical.

Yokogawa s specialists are experienced in all phases of this process. Through its consulting service, Yokogawa can help you come up with optimal migration and upgrade strategies.

With careful planning and implementation, Yokogawa can help you achieve a safe, cost-effective, and value-added hot or cold cutover migration process for your system.

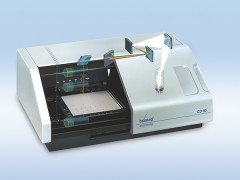

To generate the maximum return with the minimum investment and ensure that your business remains competitive, upgrade to Yokogawa s latest plant control system from a legacy CENTUM or from another vendor DCS.

工厂安全生命周期服务是网络安全生命周期方法,可以帮助客户降低安全风险,管理整个周期的工厂安全。

Honeywell and Yokogawa have both been producing Distributed Control System (DCS) platforms for decades, and both are very active in this area. In 1975, Honeywell introduced its TDC2000 platform and Yokogawa brought out CENTUM. These two competing systems emerged from a similar place, oil refining and petrochemical industries, so they started out with similar basic concepts and use cases in mind.

How to assert if migration should be required Best practices in identifying your project scope and team How to secure appropriate buy-in from the right people 7 operational capabilities to analyze when selecting a DCS system and vendor

The top challenges that drive reinstrumentation How to plan for and achieve a successful project Best practices in identifying your project scope 5 ways to improve operator effectiveness Different scenarios and best practices for updating, migrating or replacing process controls, safety systems, and instrumentation in plants

手机版|

手机版|

二维码|

二维码|