KRI 考夫曼离子源 Shift-Free Optical Coatings (Staff of Vacuum Innovations LLC )

INTRODUCTION

The deposition of optical interference coatings requires precise control of layer thicknesses and refractive indices in order to yield predictable, reliable performance. One of the challenges in the use of evaporated coatings is the porous film structure and the associated sensitivity to relative humidity and temperature which results from the low energy of the deposited molecules [1,2].

The use of an End-Hall ion source can provide added energy at the surface of the condensing film, resulting in a denser film structure for the coating molecules [3]. This denser structure can reduce or eliminate the penetration of water into the film, thereby limiting the change in refractive index and other optical parameters in the coating. This densifi cation also provides a harder, more mechanically-durable film, even at low deposition temperatures [3].

SYSTEM ConFIGURATION

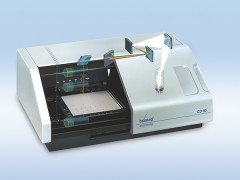

A typical system for optical interference coating deposition consists of a 0.5 1.5m vacuum chamber with planetary or single substrate rotation and one or more evaporation sources, as shown in Fig. 1. The system geometry should be arranged to provide nearly equal coating thickness on all substrates, or masks should be introduced to partially shadow regions of higher vapor fl ux [4].

The addition of an End-Hall ion source should be configured such that nearly-equal ion flux is provided to the entire substrate surface area in the coating chamber, while maximizing the utilization of the available ion flux. The modeling of ion flux with a cosine-power distribution is discussed in KRI Technical Report TR-01. The placement of the source in the chamber and the tilt of the source from vertical provide the necessary adjustments to evenly distribute ion fl ux. The determination of ion flux uniformity requires the modeling of the substrate movement, source placement and pointing using a cosine-power distribution for the ion source flux and rotation motion for the substrate [4]. An approximate starting point is to place the source directly beneath the center of the planet and direct the source at the inner edge of the annulus described by the planet motion (see Fig.1).

ION SOURCE PARAMETERS

Successful densification of oxide materials for optical interference coatings requires operation at low ion energies and high current. Energies on the order of 100eV avoid the formation of crystallites and minimize gas incorporation,

Fig.1-Deposition chamber configuration

though the use of slightly higher ion energies (up to 150eV) may be required to achieve the desired degree of densification [5].

Development of ion-assisted deposition requires knowledge of the process variables, and the influence of each on the resulting film properties. These include the ion energy, current, gases to be used, gas flow rates, and the film deposition rate.

Ion Energy

The discharge voltage determines the ion energy (eV), by establishing the potential difference through which the ions are accelerated. On an End-Hall ion source the ion energy corresponds to approximately 60% of the discharge voltage. High discharge voltages provide greater ion energies, but can increase optical absorption and defect densities. The lowest possible discharge voltage should be utilized that achieves the desired fi lm densification, usually less than about 150V.

Ion Beam Current

The ion-beam current corresponds to about 20% of the discharge current in an End-Hall ion source. An ion beam current higher than necessary is generally not a problem [5], though the presence of a highly nonuniform distribution of ion dose may lead to significant variation in fi lm densification. A key advantage of End-Hall ion sources is the availability of high beam currents. The densification of hafnium dioxide deposited over large-area substrates in a 1.1m box coater can

Densified Hafnium Dioxide Densified Hafnium Dioxide / Silicon Dioxide Mirror Densified Hafnium Dioxide Densified Hafnium Dioxide /Silicon Dioxide Mirror

Fig.3- Influence of humidity on a 9-layer hafnia/silica mirror deposited at ambient temperature with ion-assist provided by the KRI eH3000. once again, the difference between the film transmittance in ambient and dry envirnments cannot be resolved (fully dense).

for production throughput, while minimum rates are desired for greater densification. A suitable ion-assist process should be established with production deposition rates, reducing the rates as needed to achieve suffi cient densification.

IAD PROCESS EXAMPLE

These concepts were utilized to establish a process for ion-assisted deposition of hafnia/silica multilayer coatings in a 45-inch coating chamber with planetary rotation. Hafnia in particular requires a high ion dose for densifi cation, more than triple that required for other commonly-used oxides such as titania, tantala, and silica [7]. Hafnium metal and silica granules were used as the source materials in dual electron-beam sources. A KRI eH3000 with a hollow-cathode neutralizer was installed 11 from chamber center, pointing 15 from vertical toward the chamber center. The source was operated with a 150V/20A discharge using a 85/15 O2/Ar gas mixture for improved densifi cation. The coating process was established with no additional substrate heating, to allow processing of thermally-sensitive substrates as well as providing faster cycle times.

Initially, the aim was to establish a process for densification of hafnia. Since it is a significantly larger and higher-melting temperature molecule than silica, it required greater momentum and energy transfer to densify. The KRI eH3000 was operated

Fig.2- Influence of humidity on a densified hafnia layer. Note that the difference between the fi lm transmittance in ambient and dry environments cannot be resolved, indicating minimal diffusion of water in the film.

require an ion beam current up to 5A.

Gases

Ion sources typically utilize non-reactive gases such as argon, though the deposition of oxides, particularly refractory oxides such as hafnia, tantala, titania, etc., require the addition of oxygen during the deposition. The effective high-vacuum pumping speed must be sufficient to maintain the chamber pressure in the 10-4 Torr range or lower, while gases are introduced at the established process flow rates. Maintaining such a process pressure optimizes operation of the End-Hall ion source and avoids energy loss for the beam ions due to molecular collisions. Gas selection may also be used to modify the fi lm densification. For instance, the addition of a small amount (10-20%) of Ar to the O2 gas in an End-Hall source can provide significant improvements in densifi cation, since the mass of Ar is 25% greater than that of an O2 molecule. If still greater ion momentum is required, the use of Kr or Xe gases provides a substantial increase in momentum, while still using an inert gas.

Deposition Rate

The film deposition rate establishes the ion/atom ratio, which signifi cantly infl uences the fi lm densification. For a given beam current, slower deposition provides greater opportunity for the ion beam to compact the surface of the fi lm, creating a more dense coating. Maximum deposition rates are desired

Copyright 2010 by Kaufman Robinson, Inc., 1306 Blue Spruce Drive, Unit A, Fort Collins, CO 80524 Tel: 970-495-0187, Fax: 970-484-9350, Internet: www.ionsources.com

with a 20A discharge to provide maximum densification, but the use of 100% O2 through the source resulted in films exhibiting spectral shift given the ambient deposition temperature and large coating system. By modifying the gas flow to include 15% Ar / 85% O2, full densification of hafnia was achieved at 150V without intentional substrate heating. Spectral measurements of a hafnia single-layer coating at 40% RH and N2-purged 0% RH are shown in Fig. 2. Spectral shift is essentially eliminated through the use of the high-current eH3000, while enabling the coating to pass severe abrasion testing per MIL-C-675.

Silica can be expected to densify at lower ion source power, so ion source output may be reduced. However, it is often easier to maintain the source at constant output for all layers, provided suffi cient densification is achieved. Fabrication and testing of a 9-layer multilayer high-reflector coating was performed under identical process conditions. The use of an abbreviated high-reflector coating was utilized, since it exhibits greater sensitivity to humidity shift. The results are shown in Fig. 3.

The measurements of both the single hafnia layer and the hafnia/silica multilayer exhibit no spectral shift as the ambient humidity of the surrounding environment is varied. This indicates an absence of porosity in the fi lm, confirming suffi cient ion flux was present to fully-densify both the hafnia and silica layers without the use of substrate heating. It should be noted that operation of the ion source will lead to some heating of the substrate surface, and process development must be matched to the length of deposition and the relative thermal sensitivity of the substrate material.

ConCLUSIONS

The use of an End-Hall ion source provides high current output sufficient to fully densify hafniasilica multilayer coatings in a production-scale electron-beam deposition system. As larger area coatings are deposited in production deposition systems, the required beam current increases, necessitating the use of larger ion sources such as the KRI eH3000. Additionally, should the use of 100% O2 through the ion source prove insufficient for the degree of densification required, the use of a low fraction of a more massive gas such as Ar, Kr, or Xe may be incorporated to provide full densification at low beam voltage. Careful determination of source location and pointing can lead to uniform ion flux distribution over large substrate areas, making the integration of an End-Hall source in a production process highly effective, even for large optics.

REFERENCES

[1] J.B. Oliver et al, Optimization of laserdamage resistance of evaporated hafnia at 351nm, Proc. SPIE 7132 (2008).

[2] J.B. Oliver et al, High precision coating technology for large aperture NIF optics, in Optical Interference Coatings, OSA Tech. Digest, p. ThD2, OSA, Washington D.C. (2001).

[3] H.R. Kaufman and R.S. Robinson, End-Hall ion source,

U.S. Patent 4862032 (1989).

[4] J.B. Oliver and D. Talbot, Optimization of deposition uniformity for large-aperture National Ignition Facility substrates in a planetary rotation system, Appl. Opt. 45, 3097-3105 (2006).

[5] H. Kaufman and J. Harper, Development and Applications of Ion Sources, Proc. of SVC (2007).

[6] A. Anders, Plasma and Ion Assistance in Physical Vapor Deposition: A Historical Perspective, Lawrence Berkeley Nat. Lab. (2007).

[7] H.R. Kaufman and J.M.E. Harper, Ion Doses for Low-Energy Ion-Assist Applications, J. Vac. Sci. Tech., A22 (1), pp. 221-4 (2004)

其他产品

电话:+86-21-5046-3511

邮箱:ec@hakuto-vacuum.cn

地址:上海市浦东新区

新金桥路1888号36号楼7楼702室

201206

详细资讯

平台首页|

KRI 考夫曼离子源

- 下一篇:KRI 考夫曼离子源

- 上一篇:考夫曼霍尔型离子源手机壳颜色镀膜和3D玻璃镀膜

打赏

免责声明:

本网站部分内容来源于合作媒体、企业机构、网友提供和互联网的公开资料等,仅供参考。本网站对站内所有资讯的内容、观点保持中立,不对内容的准确性、可靠性或完整性提供任何明示或暗示的保证。如果有侵权等问题,请及时联系我们,我们将在收到通知后第一时间妥善处理该部分内容。

本网站部分内容来源于合作媒体、企业机构、网友提供和互联网的公开资料等,仅供参考。本网站对站内所有资讯的内容、观点保持中立,不对内容的准确性、可靠性或完整性提供任何明示或暗示的保证。如果有侵权等问题,请及时联系我们,我们将在收到通知后第一时间妥善处理该部分内容。

扫扫二维码用手机关注本条新闻报道也可关注本站官方微信账号:"xxxxx",每日获得互联网最前沿资讯,热点产品深度分析!

0 条相关评论

推荐图文

推荐新闻资讯

点击排行

手机版|

手机版|

二维码|

二维码|